The theme of this year’s Kilmer Conference was “Continuity: Fostering Our Future” which is linked to the conversations we have in previous Kilmer Conference from 2016 to 2019 “End-to-End (E2E) Microbiological Quality and Sterility Assurance”.

Ethylene Oxide Residual Analysis

Because of its broad material compatibility, ethylene oxide (EO) is frequently used to sterilize medical equipment. It’s possible for EO to leave a residue on the material being sterilized. The following are the residues that may remain following sterilisation:

- Ethylene Oxide (EO) is a possible byproduct of processing.

- Ethylene Chlorohydrin (ECH) is a potential by product of EO’s interaction with free chloride ions.

- Ethylene Glycol (EG), a byproduct that may result from the interaction of EO with water.

Ethylene Oxide (EO) Sterilization Validation

Prior to beginning routine ethylene oxide sterilisation, a product with a sterile claim needs to complete a validation process to ensure the Sterility Assurance Level claimed is met according to ISO 11135.

An Ethylene Oxide (EO) Sterilization Validation is designed to assist the manufacturer in the development of a sterilization process that delivers the appropriate sterility assurance level and ensures repeatability for each product type developed.

Medistri drives sharp increase in sterilisation of medical devices with integrated electronics during Research & Development phases.

Medistri’s Switzerland Plant in Domdidier is optimised to help innovative companies scale faster and remove friction to their development cycles. And many of the Medical Devices most complex and innovative products contain electromechanical parts.

Medistri’s Biocompatibility Testing for Medical Devices impacts healthcare companies in more than 20 countries around Europe.

The company’s laboratory provides Biocompatibility Testing for Medical Devices according to ISO 10993. Working primarily with customers across Europe in Austria, Belgium, Finland, France, Germany, Greece, Ireland, Italy, Norway, Denmark, Israel, Switzerland, Luxembourg, Croatia, the Netherlands, Portugal, Hungary, and the UK.

Medistri gets ahead with new renewable energy solutions for its sterilization and laboratory facilities.

Medistri announces in 2022 that 100% of its sterilisation & laboratory facilities are moving to 100% renewable electricity.

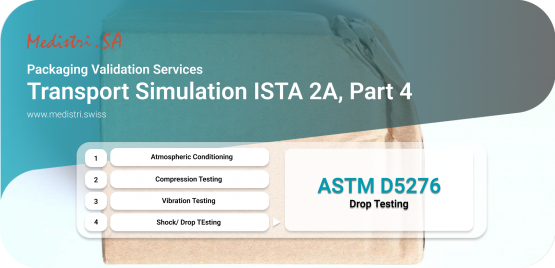

Transport Simulation ISTA 2A, Part 4 - Drop Testing

The ISTA 2A Transport Simulation standard is designed to evaluate ready-to-ship packed items weighing up to 68kg. ISTA 2A standard tests a packaging system’s ability to withstand the physical stress of transportation throughout the product’s supply chain to the final users. The standard is issued by the International Safe Transport Association (ISTA), an organisation devoted to understanding the expectations of secure transport services.

Transport Simulation — ISTA 2A, Part 4 - Drop Testing

The ASTM-D5276 standard test method for drop test of loaded containers evaluates the capability of a container to withstand the sudden shock resulting from a free fall, or the capability of a container and its inner packing to protect its contents during the sudden shock resulting from a free fall.

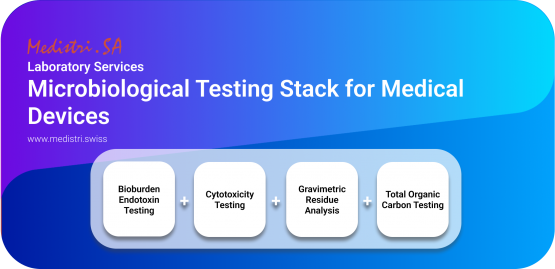

Microbiological Testing Stack for Medical Devices

Developing innovative medical device technology is a high-risk operation.

That’s why start-up ventures to large established medical devices manufacturers use Medistri’s laboratory testing services to deliver accurate and reliable results for all their testing needs.