👉 What is Vibration Testing?

Packaging are exposed to a variety of stressors throughout the distribution cycle, including unpredictable vibrations, which might undermine their protective effectiveness.

Vibration testing establishes a product's capacity to endure the stressors it will face during its lifecycle. The testing primarily mimics the stressors that occur during transportation.

The purpose is to analyse the properties of both the packaging shipping unit as well as the final product, and evaluate if the sterile barrier integrity sealing is not damaged when faced with random vibration inputs.

There are two primary types of vibration testing the we can follow:

1️⃣ Random Vibration Testing: Which tests the products when faced with vibrations that involve multiple frequencies at once.

2️⃣ Fixed Vibration Testing: Which test the samples when faced with vibration one frequency at a time.

These 2 vibration testing method allow us to mimic the damages that these vibration forces may produce in a real-world distribution context.

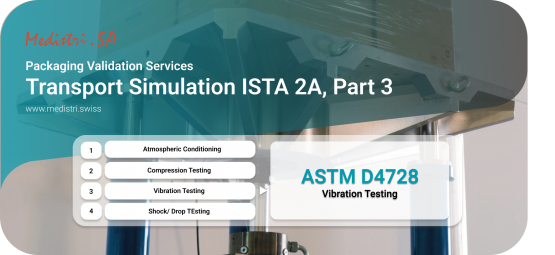

👉 What is ASTM D4728?

The American Society for Testing and Materials (ASTM) developed ASTM D4728, a random vibration testing guideline for shipping units that is part of the ASTM standards list. The ASTM D4728 standard defines how to carry vibration testing on a shipping unit in order to determine how it behaves to real-life vibration stressors.

👉 What is Packaging Validation?

The validation of packaging stems from the need to ensure the quality of products across the many steps in your distribution cycle: from shipping & storage to final user. It is a common requirement for many product categories, including a strong emphasis on the packaging quality requirements for the medical and pharmaceutical industries.

👉 What are the types of Packaging Validation?

Packaging Validation for medical devices & pharmaceutical goods is segmented into three categories.

✅ Environmental Conditioning

✅ Transport Simulation (or also known as Transit Testing)

✅ Integrity Testing (or also known as Sterile Barrier Integrity Testing)

👉 What is ISTA 2A?

The ISTA 2A Transport Simulation standard is designed to evaluate ready-to-ship packed items weighing up to 68kg.

ISTA 2A standard tests a packaging system's ability to withstand the physical stress of transportation throughout the product’s supply chain to the final users. The standard is issued by the International Safe Transport Association (ISTA), an organisation devoted to understanding the expectations of secure transport services.

👉 What is ISTA 2A’s test sequence?

ISTA 2A is composed of 4 testing types:

1️⃣ Atmospheric Conditioning

2️⃣ Compression Testing

3️⃣ Vibration Testing

4️⃣ Shock & Drop Testing

📦 According to ISO 11607-1

ISO 11607-1 specifies the requirements related to the compliance of the packaging for sterilised medical devices, including materials, sterile barrier systems and packaging systems.

🎯 To learn more about our ISTA 2A Transport Simulation, Vibration Testing & Packaging Validation Services, visit on our website at www.medistri.swiss or directly contact our team at [email protected].

- The Medistri Team

#Medistri