Packaging

The complete range of tests

Transport Simulation Testing

- Atmospheric Preconditioning

- Atmospheric Conditioning

- Mechanical Handling Test

- Compression Test

- Concentrated Impact Test

- Free Fall Drop Test

- Fork Handling Test

- Low Pressure Test

- Loose Load Vibration Test

- Fixed or Random Vibration Test

- Incline Impact Test

- Rotational Drop test

Medistri can validate your packaging according to ISTA 2A, ISTA 3A, ASTM D7386, ASTM D4169.

Should you fully validate your packaging system or should you simply test one particular characteristic of your sterile barrier system, Medistri laboratory is accredited and highly experienced for the most common test method provided in ISO 11607-1.

Sterile Barrier System Integrity Testing

- Accelerated Ageing Tests according to ASTMF1908

- Real Time Ageing Tests

- Visual Inspection Tests according to ASTMF1886

- Dye Migration Tests according to ASTM F1929 & F3039

- Bubble Emission Tests according to ASTM F2096

- Seal Tensile Strength Test according to ASTM F88

- Peel Strength Test according to EN 868-5

- Burst Test according to ISO2758

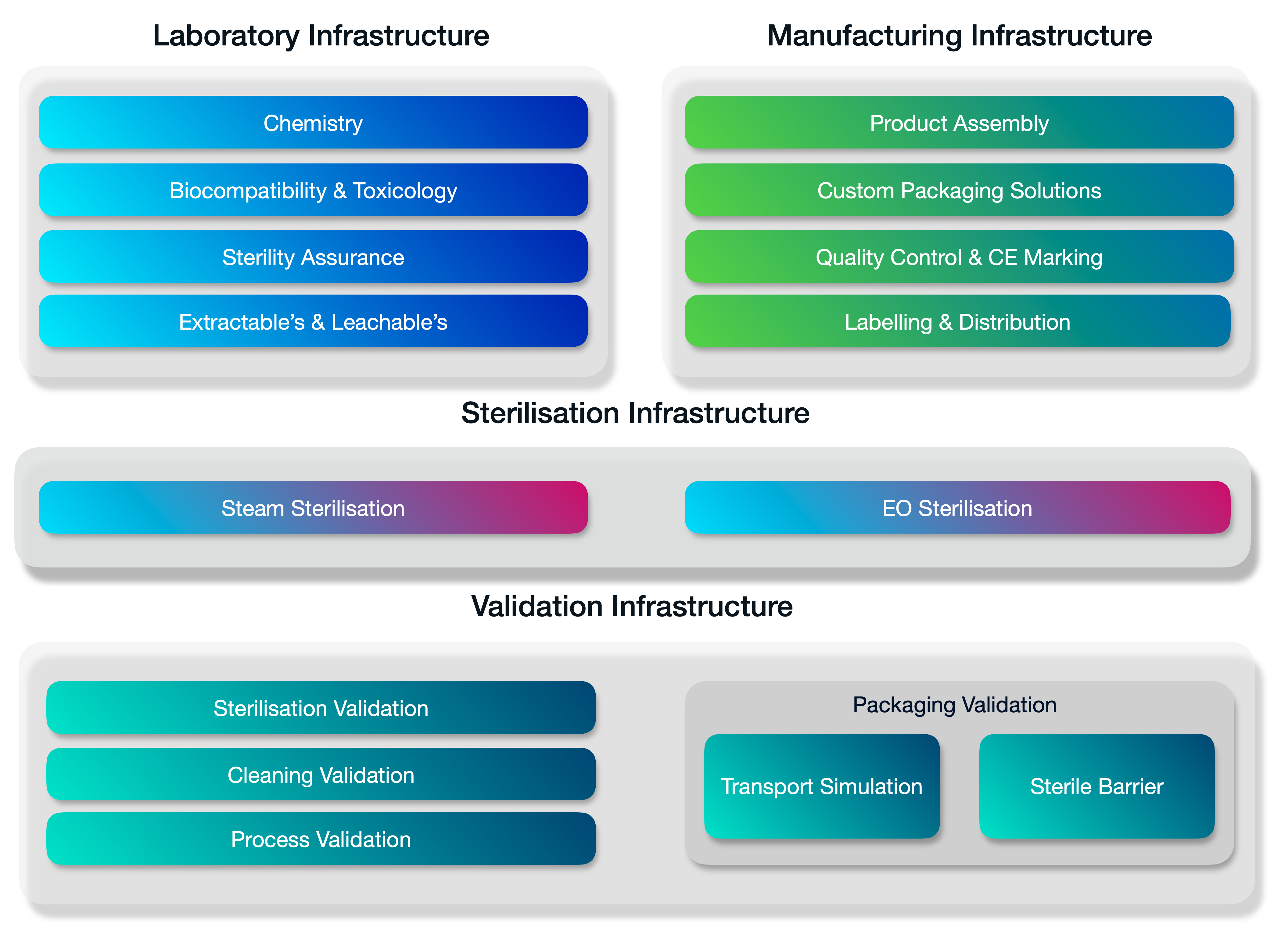

A fully integrated stack of services.

Medistri is continually innovating our in-house range of services. We’re expanding our services to offer a complete integrated suite of solutions for the innovative healthcare companies. Organisations of every size — from startups to large enterprises use our suit of services to grow & optimise their business.

Medistri combines all it’s technical infrastructure together and places quality at the heart of our day-to-day operations. Allowing you to simplify your supply chain management and focus on growth.

Discover how our customers use Medistri's stack of integrated services ➝

Biocompatibility Testing for Medical Devices

Complex Medical Devices need to assess the biocompatibility of their medical device materials and processes by taking a risk-based approach to their biological safety evaluations.Our laboratory takes into consideration the materials, processing, and historical use of the device. This allows to perform a comprehensive assessment of biological responses for each medical device in relation to its safety.

Medistri’s Biocompatibility testing performed according to: ISO 10993

Manufacturing Services

During the development of your product or even at the prototyping phase, Medistri can provide you with a custom solution that fit to your manufacturing requirements. From Product Assembly to Integration, Cleaning, Custom Packaging, Labelling, CE Marking, Quality Control and even Distribution & Logistics

Sterilisation Validation

Prior to beginning routine sterilisation, a product with a sterile claim needs to complete a validation process to ensure the Sterility Assurance Level claimed is met.

Work with Medistri to Mitigate risks. Improve your product's safety. Strengthen your Supply Chain.

Why Packaging Validation.

- Shortened packaged development time and confidence in product launch.

- Protection of products and profits with reduced damage and product loss.

- Increase customer satisfaction.

Join a growing number of innovative healthcare companies that are using our services to validate their packaging.

Are you ready to get started?

Contact us and our qualified team will respond.